Application: Boiler Feedwater Heaters via Direct Steam Injection

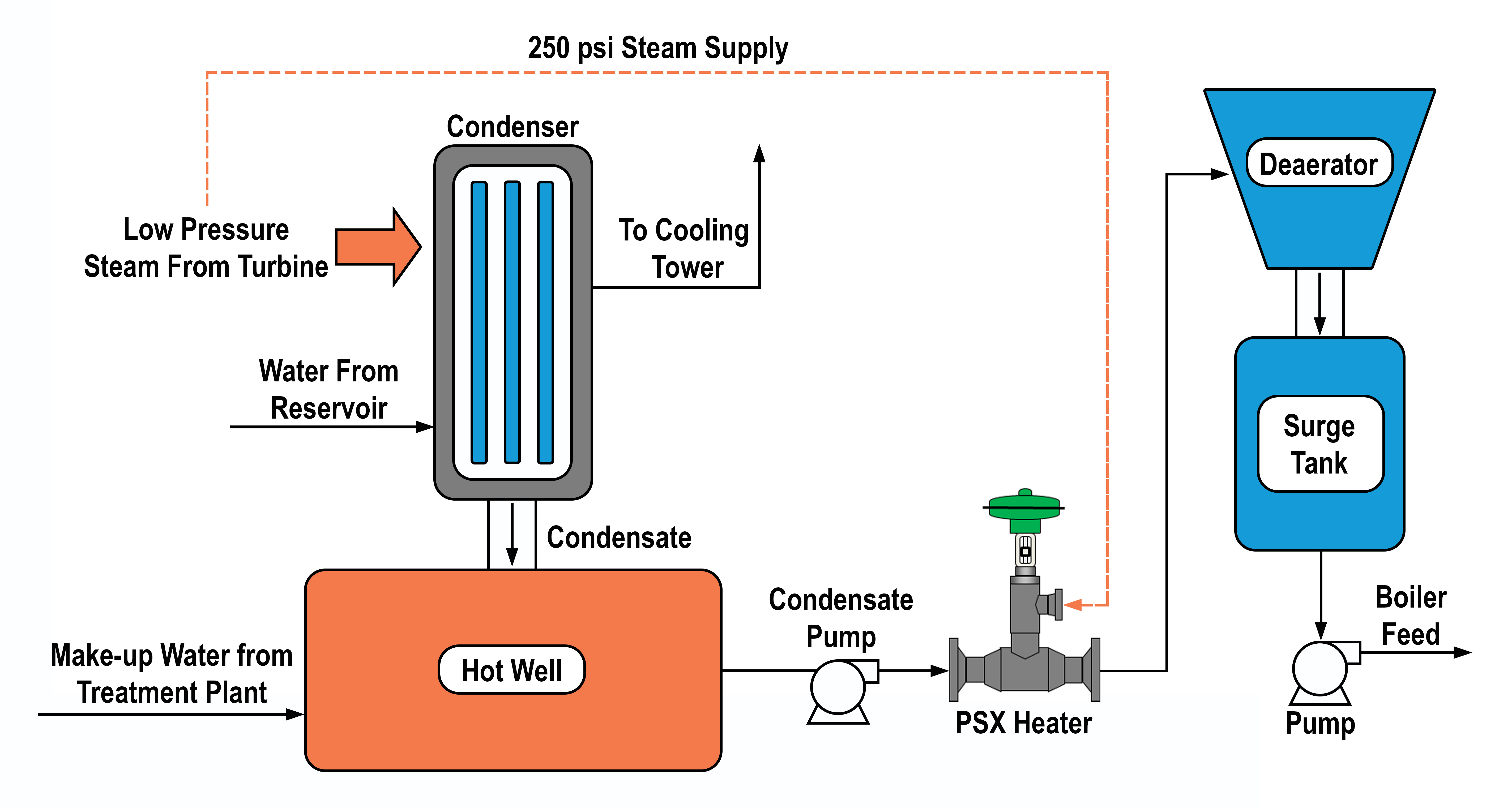

Power generating plants utilize steam boilers to produce electrical energy for their operation. These boilers often have feedwater heaters, which are an integral part of the plant’s thermodynamic cycle. The presence of the heaters in the cycle improves the thermal efficiency of the power plant by lowering the amount of thermal energy required to generate a given amount of electricity by re-using produced steam in a heat exchanger to heat feedwater prior to the Deaerator (Fig. 1).

Issues Associated with Boiler Feedwater Heating

- Heat exchangers are prone to mineral and scale build-up on the internal components. This scale build-up reduces their thermal efficiency and requires costly cleaning and replacement of damaged components.

- Mineral & scale build-up can lead to plugging/fouling issues, which increases energy consumption from the condensate pumps.

- Replacement of the heat exchangers requires considerable floor space and foundation improvements because of their size, weight, and cleaning access requirements.

ProSonix Direct Steam Injection Heater Solution

ProSonix direct steam injection heaters are an ideal solution for boiler feedwater preheating, offering smooth, reliable, and precise heating of the feedwater tank. Unlike conventional steam spargers, our heaters internally modulate to inject steam directly into the feedwater at high velocity through a broad operating range. The high velocity steam ensures the heater will operate without plugging or fouling, and without the noise and vibration often seen with the original equipment steam spargers. With their compact design, ProSonix heaters allow for easy installation either in the feedwater piping or as a tank sparger, requiring minimal space and providing an efficient, reliable, and cost-effective solution.

To find out how much you could save by heating your boiler feedwater, check out our calculator here.

Key PSX Heater Direct Steam Injection Benefits

- Stable Operation – The Internally Modulated steam control design of the PSX heater controls the steam mass flow and not the steam pressure, thus eliminating steam hammer and vibration issues.

- Lower Maintenance – Due to the PSX heater’s self-cleaning design (no scaling or plugging/fouling).

- Low Pressure Drop – Across the PSX Heater (typically 1-2 psig), reducing pump integration issues and flow disruptions.

- Economical Installation – The PSX heater can be installed in the piping with no floor space requirements.

- Precise Temperature Control – (typically +/- 1 °F) allows for a more reliable heating process.

- High Turndown – On both steam and liquid, allowing for process flexibility and variations in process conditions.

See how ProSonix® can help you!

Complete the form below to get in touch with our experts and request a custom quote for your application today.